Siemens is the world leader in automation technology, which means its products are a vital asset every Kiwi business should be able to access. Whether it’s industrial automation, electrification, or digitalisation, Siemens products are second-to-none when it comes to energy efficiency and resource preservation.

Any product from the Siemens line is designed to optimise production, minimise cycle time, and reduce waste. In essence, they are built for the factory owner, the manufacturer, and the food and beverage production professional. Anyone ready to scale up their automation and outdo their competitors needs Siemens.

As the specialist supplier of Siemens automation and drive components and technology in New Zealand, we are proud to have an extensive range of Siemens products that NZ manufacturers need to do what they do better.

If you are exploring this brand, you’re in the right place. Dig in to uncover which Siemens products are available in New Zealand, and where they fit into your factory floor.

Siemens Controllers

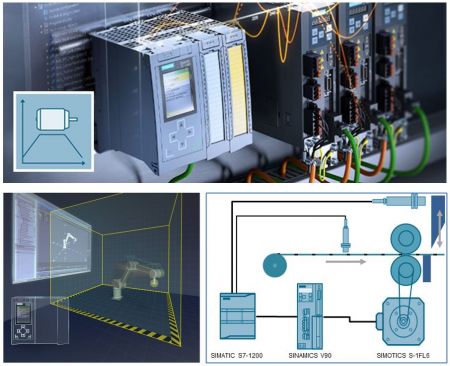

Controllers are the brain of any automated system. They take in data from sensors, process it according to a programmed logic sequence, and send commands out to motors, actuators, and other field devices. When you install these, they will keep your line running smoothly, requiring only very occasional manual intervention (if any).

We trust the Siemens products NZ manufacturers have already come to rely on, so these Siemens controllers are an excellent investment if you are looking to scale toward more precise performance across your factory floor.

When it comes to controllers in the Siemens products NZ range, you have your pick. For example, the SIMATIC s7-1500 is the flagship controller of the line, designed specifically to handle high-performance daily life on the factory floor. Alternatively, the S7-1200 PLC is a great example of a simple, flexible solution you can test out if you are just beginning your industrial automation exploration.

Siemens Drives

Industries across the board, from manufacturing to food and beverage, need to be energy-efficient and precise to achieve profitability. While this might seem like an exclusively high-level issue, something as relatively small as your drivers can make an enormous difference.

Siemens Drives are what control the speed, torque, and position of electric motors. In other words, they are there to make mechanical systems smarter and more adaptable. Siemens products in NZ, specifically their drives, are designed to reduce power consumption compared to other drives and extend equipment life, both of which help pay off the upgrade expense faster.

In the Siemens products range, we have compact drives like the SINAMICS G120C for more general-purpose applications, or you can go specialised with a model like the SINAMICS G120X, which is designed for infrastructure applications. In the servo drive range for precise motion control, there are the Sinamics S220, S120, S210 and S200 ranges. These cover the performance spectrum from cheap and cheerful to ultra-high performance.

Siemens HMIs

HMIs form the communication bridge between your people and your automated systems. They allow operators to monitor processes, adjust settings, troubleshoot faults, and track performance in real time. You’ll know a great HMI from its ability to empower your people to work smarter, instead of just displaying data that humans need to spend a lot of time interpreting.

What sets Siemens HMIs apart is how well they integrate with the wider ecosystem of Siemens products that NZ manufacturers might already be relying on, which is vital. Disconnected systems help no one.

With these, operators can see exactly what matters in real time, maintenance teams gain clarity over faults or inefficiencies, and engineers can customise displays around their unique processes. The result is a safer, clearer, more responsive production line.

Siemens products NZ-wide divide their HMIs into three categories: Basic, Comfort, and Mobile panels. The first are robust and cost-effective, the second offer a more comfortable, advanced interface, and the third are handheld HMIs designed for factory workers who need to be on the move. All of them help your operators to stay connected to your production line, so nothing gets dropped.

Siemens I/Os

I/O modules are the backbone of communication in any automated industrial system you plan to implement. These input/output modules gather data from the line's sensors and allow the controllers/PLCs to send instructions to the components that need them based on what they find. Without I/Os, your controller would essentially have nothing to work with.

These are the components that make scalability possible in high-performing industrial systems (or create these systems where there are none yet). You don’t have to rewrite your entire system architecture to expand, which is vital not only now, but in the future when the standards for industrial automation inevitably evolve once again.

Model families from within the Siemens products NZ range each have unique applications as I/Os. For example, the SIMATIC ET 200SP is a modular system designed for distributed control, whereas the SIMATIC ET 200MP is designed for centralised control.

In short, these four categories shape the four corners of your next industrial automation upgrade. If you are seeking a world-leading brand to trust that also supplies New Zealand, then Siemens is the way to go.

Browse our large range of world-leading Siemens products in NZ.

We are CNC Design, New Zealand’s specialist supplier of Siemens products. If you are looking for new and exciting ways to revolutionise your approach to automation in manufacturing, health, energy, or any other sector, we can help.

Browse our extensive range, or reach out to discuss changes on a larger scale with our in-house automation designers, who are experts at supporting your team in implementing Siemens products NZ manufacturers use to scale.