Siemens have recently re-released it’s S210 servo drive range, and called it the S210 (New).

The drive features a new chip set / hardware architecture designed to support the currently released functions, plus additional functions planned for future firmware releases.

There are various updates to enhance the ‘digitisation’ life cycle of the drive, but the real value proposition CNC Design sees for it’s customers is the first time we see safety functions to performance level PLe (With respect to ISO13849-1) in our servo drive offering, without needing additional safety componentry. This is the highest safety reliability rating within this standard. The rating not only applies to Safe Torque Off (STO) but also extended safety functionality. In this initial release with firmware version 6.1, the safety functions to PLe are:

STO (Safe Torque Off)

SBC (Safe Brake Control)

SS1 (Safe Stop 1)

SLS (Safe Limited Speed)

SDI (Safe Direction)

SSM (Safe Speed Monitor)

The full range of advanced safety functions you are familiar with from S120 and the original S210 will be progressively released to PLe. The next big release will be with TIAV19 schedule for the end of 2023 / first half of 2024.

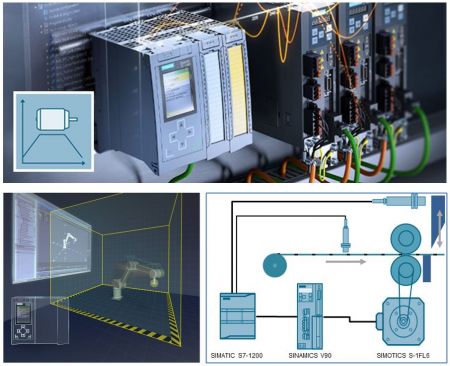

The S210 (New) can be fully engineered using TIA Portal plus Startdrive version 18 Service Pack 1. This continues the single point of truth architecture of TIA Portal from your Siemens higher level control (Simatic PLC or Simotion motion controller or Sinumerik Machine Tool Controller) and visualisation system (Siemens WinCC Comfort / Advanced / Professional or WinCC Unified) – all in the one code and configuration backup. The drive can also be used in previous versions of TIA Portal by integrating via a GSD file. However the drive would then have to be configured via the integrated webserver in the drive.

Additional Highlights

For our customers who run drives in the geothermally blessed regions of New Zealand, the drive comes with a sulphur gas resistant coating on the electronics – increasing the life span of the drives in these challenging conditions.

For those of you already using S210 (original) you will be enjoying the ‘one cable connection’ integrating the power, brake and encoder cores into the single cable between the servo motor and drive. This reduces cable laying time, and halves the work installing servo motor cables through drag chains – a real boon.

For those less familiar with the S210, it operates with the 1FK2 and 1FT2 servo motor range from the Siemens Motion Control Team. These motors are now available with the option of factory fitted planetary gearboxes. The 1FT2 range also has a host of new options, more akin to S120’s 1FK7 and 1FT7 servo motor ranges.

Hygienic Food Industry Servo Motor for S210

For applications in the food and beverage industry, where hygiene is important, Siemens produces the S-1FS2 hygienic stainless steel servo motor. This servo motor is European Hygienic Engineering Design Group (EHEDG) certified which validates it’s hygienic design and cleanability. It is not only hygienic and cleanable, but it is also rated to IP69. This servo motor works only with the S210 range of servo drives due to it’s ‘one cable connection’.

Siemens Servo Motor Families

For those of you who are unsure where the S210 fits into the Siemens Servo Motor family, the below will clear it up:

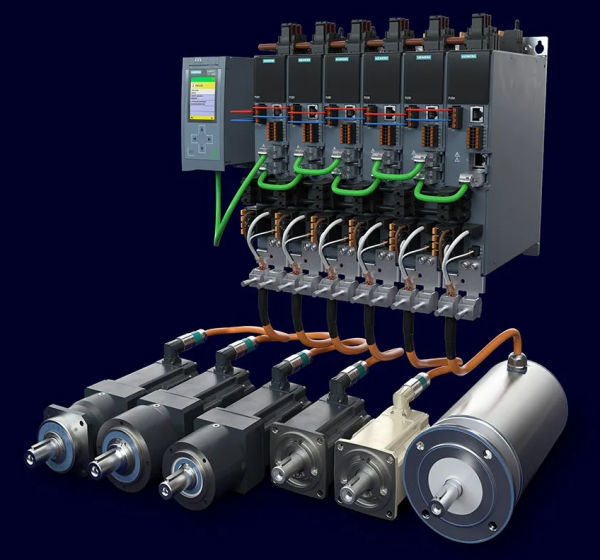

S120 – Siemens' common DC Bus, top of the line servo system. Centralised configuration for easiest drive replacement in the rare occasion of a breakdown. Huge torque / power and inertia range available. Mains regeneration available for maximum energy efficiency. The S120 can also host a wide array of technological functions on board, separate to the high level controller.

S210 – same dynamic performance as S120, but each drive must have a line supply and configuration loaded. So have a higher wiring and programming overhead than S120. DC bus sharing can be connected in many instances, but braking energy not able to be shared must be dissipated via brake resistors. Limited onboard functions when compared to S120.

V90 – Siemens value servo drive. Less performance and less features than it’s more capable cousins above, a great option for lower dynamic, simpler application.

S220 – For the Siemens ‘train spotters’ out there, the first tentacles of the next generation of top of the line servo system (to eventually replace S120) have inched out onto the market. So far a limited range of S220 infeed modules are available. Stay tuned for further updates from your specialist motion control supplier, CNC Design, as the range expands and we highlight the value proposition.

Summary

For those of you who need a servo drive set with best in market safety (To PLe), or those who need a hygienic servo motor. The S210 (new) is a no brainer. Give CNC Design a call to discuss your servo system requirements and assist in specifying an optimal servo set for your machine. Buying from CNC Design ensures you have the local support available to get you up and running as quickly and efficiently as possible, leveraging off 33 years of deep servo system supply and engineering experience.