Simatic (Siemens Automatic) as a product line started life 65 years ago. For 29 of those years, the S7-200 has graced this earth. The S7-200, S7-300 & S7-400 were initially released in 1994 to supersede the Siemens S5 system. However, all good things must come to an end, and the end has come for Simatic S7-200. 10 years ago the final S7-200 modules were discontinued, and the 10 years of guaranteed spare parts availability from Siemens has expired. As the S7-200 was not as ubiquitous as its big brother the S7-300, there are nowhere near as many spare parts floating around the world. In many instances, our PLC service team find it impossible to find an exact replacement now. Therefore, it is critical for your machine/plant up-time to create a plan to migrate your S7-200-based systems to Siemens’ extremely capable value PLC range, the Siemens S7-1200. Or if it makes sense for spare parts commonality with your other automation equipment - the ET200SP form factor PLCs.

For purely interests sake, the S7-200 is so old that the original programming software for it was released in two versions:

Step-7Micro/DOS (This DOS version of software battled on until discontinued in 2001!)

Step-7Micro/WIN (Windows version)

This permitted people using DOS operating systems to enjoy the S7-200 range without being forced into Windows for the initial years after release.

As most of our readers will know, all current version Siemens PLCs are programmable in the one common platform – TIA Portal. Therefore, choosing between an S7-1200 and ET200SP form factor (S7-1500) for your PLC upgrade doesn’t change the programming environment.

Hardware Variants

Variant 1 (original)

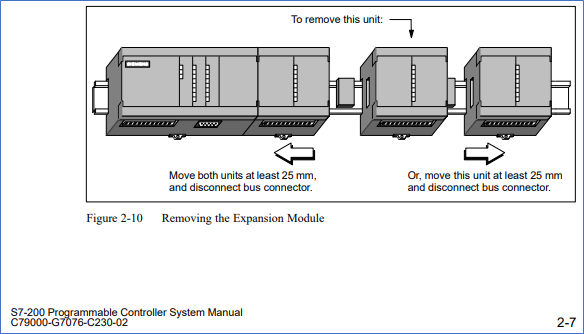

There are two major hardware variants. The original with ‘mid height’ bus connectors, as shown in Figure 1 from the 1997 Siemens S7-200 manual.

FIGURE 1: 1997 version of S7-200 with separate bus connectors

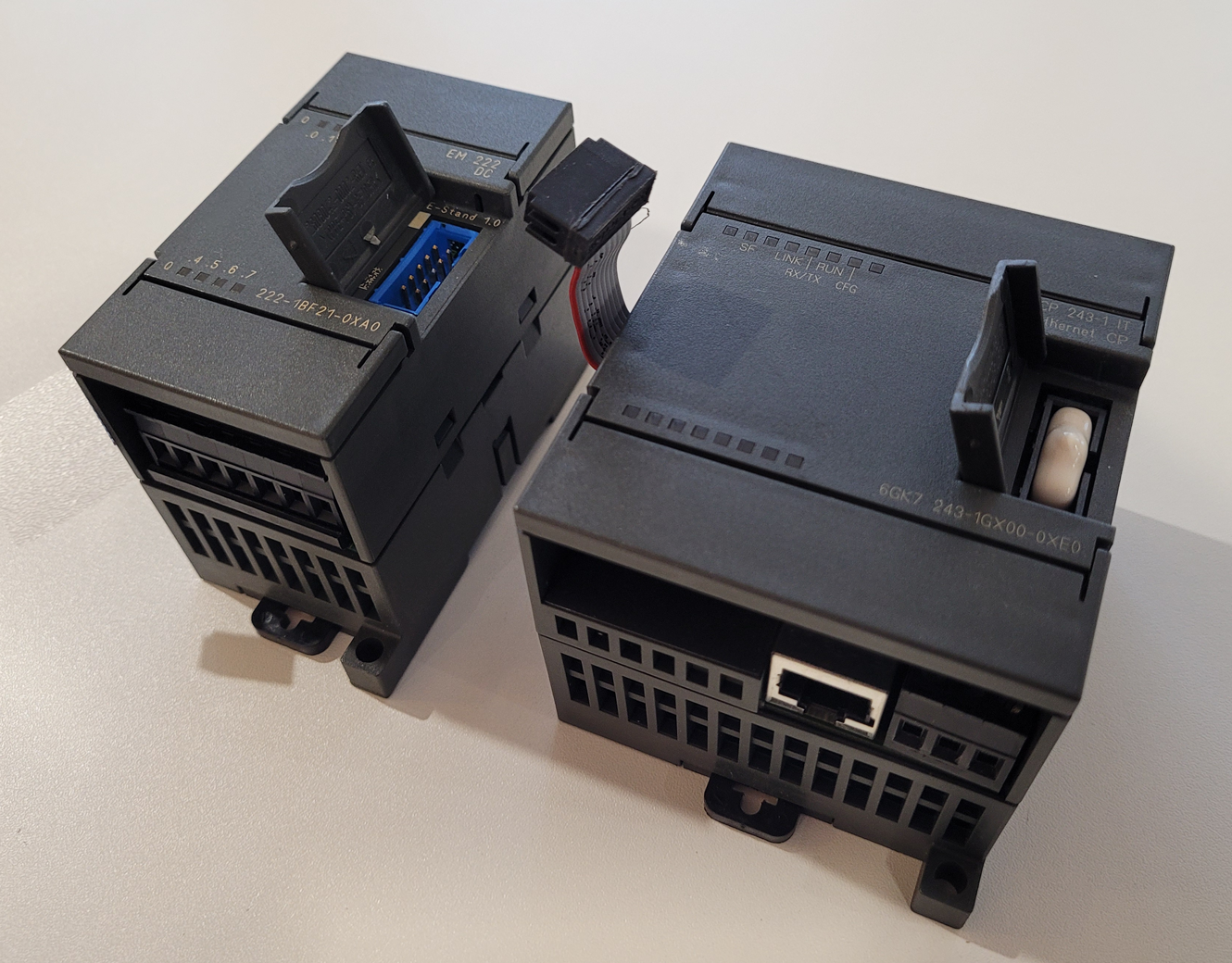

We still do come across these in the field during PLC service; a couple of I/O units from the CNC Design “museum” are shown in Figure 2. However, spare parts are pretty much non-existent now – meaning the only practical way out is an emergency retrofit. Doing retrofits in a great hurry generally means various compromises are required to meet a tight timeline, and almost always at extra cost. It is a strong suggestion that the S7-200 replacement be planned and at least partially executed early before a breakdown in a piece of equipment that will be costly or inconvenient to lose the availability of while said retrofit is undertaken. Planning will also allow one’s upgrade to be cost-optimised.

FIGURE 2: Original Hardware Version of S7-200 - mid height bus connectors

Variant 2 (Final)

The second variant changed the bus connector between the PLC and expansion I/O units to a ribbon cable with front access. This had the great advantage over its predecessor of removing the need to slide the units along the DIN rail to remove them if they needed to be split from their peers for replacement. While this version is newer, spare parts availability has also run out on these. So, the urgency to swap these PLCs out to current Siemens PLC versions is very close to the original.

FIGURE 3: Newer Hardware Version of S7-200 – front access bus connectors on ribbon cable

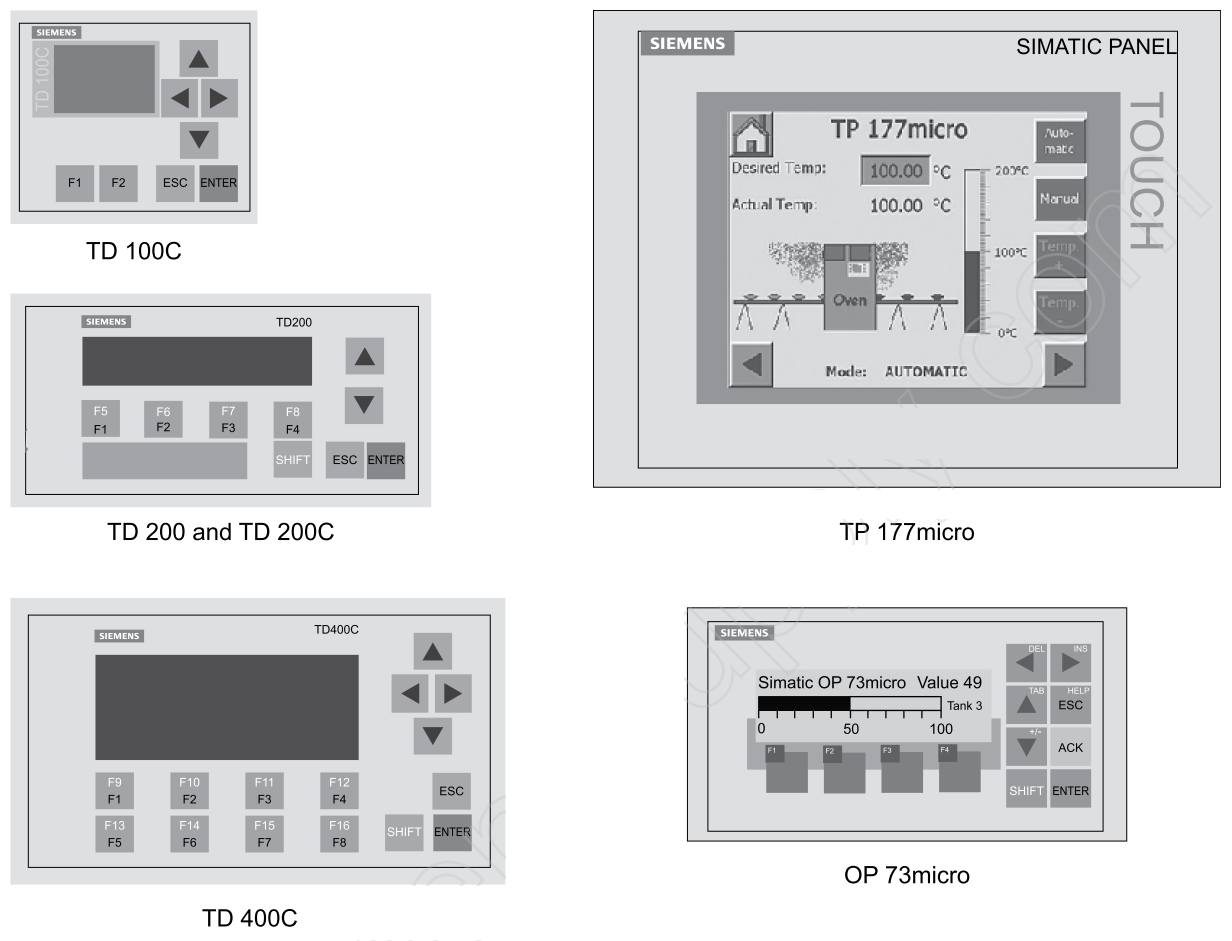

HMIs

The S7-200 had a set of Simatic Micro Panels released to augment its ‘value’ automation offering. These HMIs are shown in Figure 4. These are past their 10-year spare parts availability, so when ones HMI on their Siemens S7-200 fails, it is not a trivial task to replace it. For the second hardware version of the S7-200, CNC Design employs some cunning tricks to get Comfort panels to communicate with the S7200. However, the state of the art in HMI systems is a continually evolving and improving beast, and the Siemens WinCC Unified HMIs are increasingly taking over from Siemens WinCC Comfort panels in the market. The Unified panels cannot natively communicate with S7-200 at this stage (and likely never will be able to). So, it really is time for the modernisation of that Simatic S7-200 system.

FIGURE 4: Final Version of S7200 HMIs

Retrofit Process

We often hear the message that people do not have time to ‘take down the machine’ (or process) long enough to retrofit. CNC Design has its own bespoke wiring adaptor solution (Where a Siemens adaptor system isn’t already released). If minimising downtime is a priority, we can close to 100% pre-wire the system. We commonly do this on Simatic S5 to ET200SP PLC (S7-1500 based) retrofits. However, the same technique can be employed for S7-200. See our case study on CNC Design replaces ageing PLC systems on Interislander ferry for a great example. Stay tuned for our latest iteration of such a job – featured in an up-and-coming case study - where the machine downtime was only 4 hours for installation and commissioning!

Code Conversion

Siemens hasn’t released as higher functioning tools to convert S7-200 to S7-1500 as it has for S5 to S7 Classic (then from S7 Classic to TIA Portal). However, CNC Design has methods to speed up the process. Therefore, we can employ such techniques if you would like us to retrofit your machinery. If you are an industrial automation person or have your own industrial automation team, buy your hardware from us and we can support you to do the transition yourself.