For most manufacturers in New Zealand, the choice of a controller is rarely a decision made on a whim. It is the single most important piece of hardware on the floor because it dictates how much sleep the maintenance manager gets and how often the production line actually hits its targets.

Industrial automation is a big, fast-paced world, and Siemens controllers have worked hard to establish themselves as the industry standard across decades. While brand recognition is important, the reason they have such brand recognition is because Siemens controllers in NZ solve specific, messy problems that arise when you try to move a high volume of product through a factory.

If you’re considering bringing Siemens controllers onto your floor, read on to find out why that might be an excellent idea.

Siemens controllers are built for the realities of a factory floor.

The primary reason these controllers are favoured by engineering teams across the country is their inherent reliability in environments that are often hostile to electronics. A factory floor in New Zealand might be subject to extreme temperature fluctuations, high humidity, or significant electrical noise from heavy machinery.

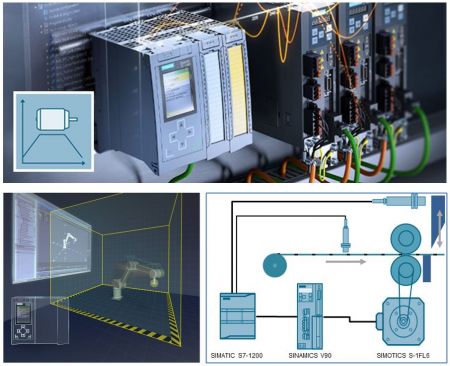

Siemens designs their hardware to withstand these conditions without the "glitching" that often plagues lower-end components. When you install a controller from the SIMATIC range, you are essentially buying a decade or more of uninterrupted service. This reliability is the foundation of any automation strategy; if the brain of the machine is prone to failure, the most advanced sensors and motors in the world won't save your production schedule.

Siemens controllers simplify safety and compliance.

One of the most significant technical shifts in recent years has been the move toward integrated safety. Traditionally, if you wanted to ensure a machine would stop instantly when a light curtain was tripped, or an emergency stop was pressed, you had to install a completely separate safety relay system. This meant more wiring, more points of failure, and a much more complex troubleshooting process.

Modern Siemens controllers (specifically those with "Safety Integrated" features) integrate both standard machine logic and safety protocols into a single unit. This reduces the footprint in the electrical cabinet and simplifies the entire architecture.

From a local compliance perspective, this is huge. It makes meeting New Zealand’s rigorous health and safety standards much easier, as the safety logic is built into the machine's core.

Siemens controllers work with other components.

While the quality of your components matters, it’s in the software environment where real efficiency gains are found. Anyone who has spent time in industrial programming knows the frustration of jumping between five different software applications to configure a drive, an HMI, and a PLC.

The Totally Integrated Automation (TIA) Portal acts as a single point of entry for the entire Siemens ecosystem. It allows an engineer on your floor to map out the entire machine in a virtual environment before a single wire is even connected.

With a unified approach like this, you can be sure that diagnostics are consistent across the board. If there is a fault in a remote I/O station, the controller identifies it immediately and can report the exact location and nature of the error. No more “search and rescue” missions for your maintenance teams when no one can figure out why a machine went down.

Siemens controllers help you to scale easily.

Siemens controllers in NZ also help you to scale like nothing else, because they are designed with growth in mind.

For example, a small-scale producer might start with a compact S7-1200 for a simple conveyor or packaging unit. As the business grows and the requirements become more complex (maybe requiring high-speed motion control or extensive data logging), the transition to the more powerful S7-1500 is relatively seamless.

Because the programming logic and the software environment remain the same, you don't have to retrain your staff or rewrite your entire codebase. No starting from scratch.

This ability to scale without "starting over" is vital for New Zealand manufacturers who need to remain agile in a global market that constantly demands we punch above our weight.

Siemens controllers help you transition to data-driven manufacturing.

We are also seeing a massive push toward data-driven production, or Industry 4.0. Taking on Siemens controllers NZ-wide helps manufacturers and other industry leaders step out of the “logic box” era of old controllers and adopt sophisticated data hubs on their lines. These beauties can communicate directly with higher-level IT systems and cloud platforms, like Insights HubMindSphere, to keep you on track.

You can track energy consumption, monitor cycle times, and use predictive analytics to identify when a bearing might be wearing out before it actually breaks. It’s a massive shift from reactive maintenance (where you only deal with a problem once it has happened) to proactive maintenance (where you anticipate problems before they occur). In other words, you’ll save thousands on downtime.

At the end of the day, a high-quality system of Siemens controllers will always equip you with what you need to grow, adapt, and outpace the local market. Of course, the hardware is only one part of the equation.

For New Zealand companies like yours, the availability of local support and expertise is just as important. Choosing a controller that is well-supported in the local market means you won't struggle to find a technician who understands the system. As thespecialist supplier of Siemens controllers in NZ, we can help with that.

Need to review your current control systems?

We are CNC Design, your local automation design specialists. With easy access to a wide array of Siemens controllers in NZ, we can offer you best-in-class components with the local support you need to reap the rewards.

Get in touch with our team or browse our Siemens range today.