If you’ve spent any time researching which totally integrated automation parts to purchase, then we don’t have to tell you how complex it can be. At times, it can feel like playing a high-stakes game of “Guess Which Part Won’t Be Discontinued Next Year.”

Today, we aim to simplify that journey for you. The temptation when embracing better automation is to over- or under-specify, both of which can cause issues down the line. You don’t need to spend money on features you’ll never use, but you also don’t want to lose $50,000 over the course of years just by trying to save $500 today.

After three decades of designing automation systems using the totally integrated automation parts out of the Siemens line-up, we understand how to pick the right parts for the job. From us to you: here is a practical look at how to navigate the Siemens portfolio without losing your mind (or your budget).

1. “Just enough” isn’t enough CPU power anymore.

Unfortunately, one of the most frequent mistakes we see in-house automation teams make is choosing PLCs based on the current I/O count. While that makes sense on paper, it’s a trap that holds you back from scaling.

The ‘Technology Objects’ (TOs) on your line represent the mechanical components new totally integrated automation parts are responsible for handling. If you buy with only your current specs in mind, you trap yourself against a wall and almost guarantee you’ll have to pay for a future upgrade.

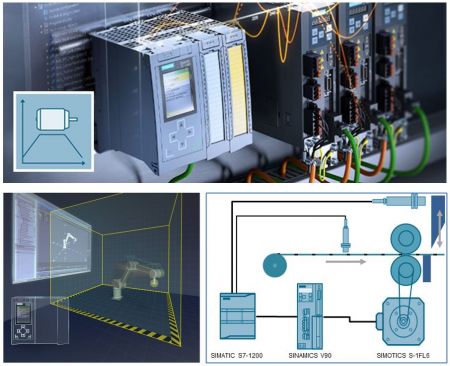

For example, the SIMATIC S7-1200 is a compact workhorse for basic logic, and no one can argue against its brilliance. If you have standalone machines or basic conveyor loops, this is the way. But the moment you start thinking about coordinated motion or high-level data logging, then you might hit a wall.

This is why it’s vital to consider whether you will be scaling your facility in the near future. If so, investing in a step-up in processing power (such as the S7-1500 compared to the 1200) will set you up for success.

2. Unblur the line between “CNC” and “PLC”.

If any of the work on your floor involves multi-axis movement like cutting or shaping, then you must choose carefully between a CNC or a PLC. PLCs, particularly SIMATIC PLCs, are excellent totally integrated automation parts if your line relies on “if-this-then-that” logic (if a pallet touches the sensor, then stops the motor).

But if you are dealing with complex pathing, such as modelling precise 3D arcs, then you want a CNC that can do the job. We recommend anything outside the SINUMERIK range, up to and including the Sinumerik ONE, the full-featured CNC that fully integrates with Siemens’ Totally Integrated Automation Portal.

One mistake some in-house upgrades run into is trying to force a PLC to perform complex pathing. While it can code a complex motion profile, a CNC controller like the SINUMERIK has algorithms like this “baked in”. In essence, you’re just picking a better tool for the job.

3. Save your engineer’s sanity with TIA Portal.

If you are an engineer or electrician installing parts for a totally integrated automation system during an upgrade, you also need to be familiar with TIA Portal. Prior to its invention, industrial software was a mess of different disconnected programs for each drive, sensor, PLC, and HMI. If one variable changed somewhere, it had to be manually updated throughout the whole line.

But with TIA Portal and Siemens parts native to the software, you can create a Single Point of Truth that your engineers will bless every day. Not only do the updates ripple across the whole line, but there are built-in proactive diagnostics that save your engineers hours of hunting for that single blown fuse.

4. Retrofit where you can to save on cost.

New Zealand’s manufacturing market is still in a period of massive growth, and we see many plant owners thinking they need to invest in entirely new machinery because their current model isn’t up to par. While this can be effective, it can also be very expensive. Ultimately, it might also be unnecessary if the machine's mechanical “iron” is perfectly fine. More likely, it’s the 20-year-old electronics that are keeping you behind.

This is where you can embrace a retrofit mindset using Siemens automation components. By our estimates, retrofitting with totally integrated automation parts out of the Siemens line is roughly 40% cheaper than buying a new machine of equivalent quality (though of course this changes case-to-case).

The machine can take on a faster, more reliable life with scalable processing power that won’t hamper your path to success.

5. Install and update with local automation support.

Finally, we recommend partnering with a local supplier and automation designer when and where you can. Proactivity is important here, as many plants upgrade only when necessary, on a Tuesday morning when their entire line has gone down.

For our money, choosing the right part also means choosing the right supply chain. We maintain a local inventory of genuine Siemens spares specifically tailored to the NZ industry.

Furthermore, we are the only Siemens Approved Partner for Industry Service in the country. That means if your motor fails, we don't just tell you to buy a new one; we can often repair and load-test it in-house, getting you back to work in 24 hours instead of 24 days.

Trust CNC Design for your TIA upgrade or installation.

Looking to map out your next upgrade or navigate a complex Siemens migration? Get in touch with the CNC Design team. We’ve probably already solved the exact problem you’re facing.