Take a moment to think about your factory floor, and find the “Old Faithful” machine in the layout. You know the one (or perhaps more than one). That massive, five-tonne piece of European or Japanese iron that’s been happily chugging away for thirty years, and could likely run for thirty more. The castings are solid, the ways are true; mechanically, this machine is a tank you’d do well to hang onto.

But the electronics? A different story. There’s a chance that the very same reliable machine is running on outdated controllers, whistling drives, and infrequent (but frustrating) glitches that put your whole line in downtime.

The easy advice here would be to purchase an entirely new machine. But in today’s economy, that scale of investment isn’t necessarily the smartest move. More likely, you can embrace totally integrated automation and update what you already have with the right parts.

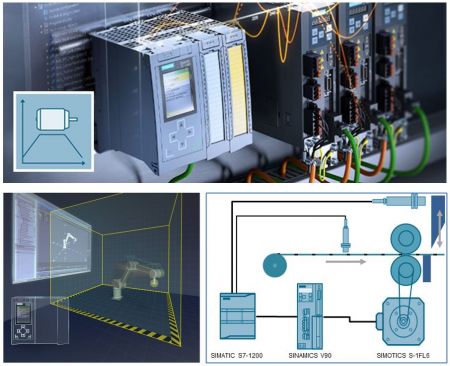

Today, we’re walking through the benefits of transforming this legacy asset of yours with fully integrated automation components from the Siemens range.

You get more speed without moving faster.

It sounds like a Catch-22, but with decades of Siemens data backing the statistic, an upgrade to Totally Integrated Automation parts usually results in a 15% to 25% increase in productivity without any changes to the physical motors or belts. It’s all in the processing power.

Old controllers have inherent bottlenecks, thanks to how they calculate movements. They can only look ahead a few lines of code at a time, which can cause stuttering or slowdowns during complex pathing.

If you swap out your old control system for a SIMATIC S7-1500 or similar, you give the machine an IQ boost. These Siemens processors are far more equipped to handle complex algorithms instantly, so your floor operators will observe both smoother motion and faster cycle times.

Full visibility during repairs or faults.

We’ve all been there: a machine stops, a red light blinks, and no one knows why. Your best engineer spends four hours with a multimeter, only to find that a loose $5 cable is the culprit.

The biggest benefit of installing Totally Integrated Automation parts, specifically configured within TIA Portal, is the shift from blind to predictive maintenance. Modern drives and controllers can “talk” to one another on the line, providing real-time information to your engineers via their HMI. During a fault, this integrated system will display exactly what’s wrong, turning a four-hour outage into a ten-minute fix.

More efficient use of energy on the floor.

Totally Integrated Automation parts come with a big energy promise: they are likely to significantly reduce the size of your energy bill. With rising line charges and sustainability targets, this can be a massive boon well-worth the cost of the installation.

But why are they so much more efficient? Well, old-school drives dissipate the generated braking energy through large resistors, converting it into heat. Siemens drives, such as the SINAMICS S120 or the brand new SINAMICS S220, can be configured to perform a different function: regenerative braking.

Essentially, the energy generated by a decelerating motor on the line gets cleaned up and fed back into your facility’s internal power distribution grid, or even used by another motor on the same machine to accelerate in turn. Over a year of high-volume production, that cycle-by-cycle accumulation can add up to a major discount on your power bill.

A future-proofed line that’s ready to scale.

To your engineers, there is nothing more terrifying than needing to find a replacement part for a 20-year-old proprietary controller, on a random Thursday, when the entire line has ground to a halt. The only available solution is triple the usual cost and can only be found in Eastern Europe.

When you choose Siemens Totally Integrated Automation parts, what you’re actually doing is adopting a better ecosystem. These parts set the global standard, one characterised by long lifecycles and efficiency good enough to scale any plant. Even if a plant is eventually phased out, Siemens will provide a “spare part” period of ten years.

Furthermore, because CNC Design is New Zealand’s only Approved Partner for Industry Service, we keep many of the parts you actually need right here in the country. That means we can help you service, replace, or step sideways within the same technological ecosystem when the time eventually comes to change things up a decade or two from now.

Adding a ‘Digital Twin’ to the line-up.

Finally, we have to pay homage to the Digital Twin.

This is a particular benefit that comes from moving to the SINUMERIK ONE platform during an upgrade, and is well worth considering if you have high staff churn on your floor. Essentially, we can create a ‘Digital Twin’ of your machine before ever touching it physically, which is a virtual model that lives off your floor.

With a Digital Twin, your team can train new operators on the interface without stopping production on the floor, test new products or parts in a silo, and optimise the machine’s pathing to shave seconds off your cycle time.

In other words, you don’t have to fear any future upgrades. You’ll understand exactly how your machine will perform before the first wire is even cut, and that’s vital for any future installations of Totally Integrated Automation parts.

Trust CNC Design to pair you with the right Siemens products.

As New Zealand’s one and only authenticated supplier of the Siemens Sinumerik product line, and New Zealand’s expert distributor of the remainder of the Siemens Industrial Automation portfolio, we are proud to connect plant owners, OEMs and their engineers with everything they need to upgrade their lines or machines.

Talk to us today about complex integrated automation design, or to simply source the part you need to get up and running again.