In any modern industrial setup, you’ll see a constant conversation happening between the hardware that does the heavy lifting and the person tasked with overseeing it. For decades, this conversation has happened on relatively basic terms. Physical buttons pushed, switches toggled, perhaps a few analogue gauges to keep an eye on vital metrics.

But today, that interaction has moved almost entirely to the digital realm via the Human Machine Interface (HMI). It’s easy to look at an HMI and just see it as the screen on the side of the machine, but its true value is unlocked only when it’s perfectly synced with the controller, the brain of the operation.

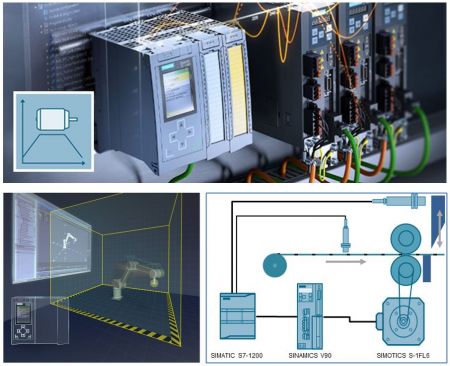

Siemens HMIs and controllers work together seamlessly to help human operators manage the line without losing any vital data, thanks to these products being among the best in the world. Read on to learn about how these two extremely important components can provide you with better control.

How the interface has evolved:

It helps to look at what an HMI actually does in a modern context. At its simplest, a Human Machine Interface translates complex machine data into something a human being can understand and act upon.

However, when you look at diverse human machine interface applications (ranging from high-speed food packaging lines to heavy timber processing), you realise that the HMI is also providing a window into the health of the system.

If the controller and the interface are from different manufacturers, a "translation layer" is often required. This adds latency, increases the risk of data errors, and makes the initial programming phase much more complicated.

Working with Siemens controllers and human machine interfaces grants you an inherent understanding of your components, so no one on the line is struggling to interpret mismatched data or bridge the divide between components not designed to work together.

With that in mind, let’s look specifically at how a Siemens-to-Siemens setup grants you better control.

How Blending Siemens Controllers and HMIs Gives You Control

You work with TIA Portal.

In a traditional setup, your engineers might have to create a list of variables, or "tags," in the controller and then manually recreate it in the HMI software. It is a tedious, repetitive process that is ripe for human error. With a Siemens-to-Siemens setup, the HMI has direct access to the controller’s database.

For example, if you change a variable name in the PLC code, it updates automatically across the interface. For Kiwi manufacturers like yourself looking to reduce downtime or commission a new line quickly, this "single point of truth" saves immense time and provides unbeatable control.

Downtime takes no time at all.

The benefits of this tight integration become even more apparent when something goes wrong. Every minute of downtime on a production line is a direct hit to the bottom line, and the biggest delay in a repair is often the time spent figuring out exactly what failed.

Siemens controllers have "system diagnostics" built into their core. When an integrated Siemens HMI is used, these diagnostics are displayed automatically without the engineer needing to write a single line of extra code. If a specific drive trips or a sensor loses power, the HMI can show a clear, plain-English message rather than a cryptic hex code.

This is a massive benefit for any companies that operate regionally, where technical support isn’t always around the corner.

Predictive data helps you anticipate problems.

Zoom out, and you can see a general shift across various industries toward more data-heavy requirements. Now, industry leaders must track energy usage, monitor cycle times, and even predict when a part might fail just to stay ahead of the competition.

Modern Siemens controllers and HMIs can handle this easily. The line is designed to log data directly to a CSV file or communicate with higher-level cloud systems for remote monitoring. Because the HMI is already so closely tied to the controller, gathering this data doesn't require complex "man-in-the-middle" hardware.

On the whole, this makes the path to an Industry 4.0 setup much more straightforward and cost-effective for local businesses like yours.

Your operators get a better user experience.

Any Human Machine Interface applications shine because the devices themselves are intuitive enough that a new operator can understand the machine’s status at a glance.

When the controller and HMI are paired correctly, the interface can also handle "user management" more effectively. You can easily set different levels of access, ensuring that a trainee can only view data while a senior technician has the permissions to change critical setpoints. This adds a vital layer of operational safety to your floor.

Your floor is far more scalable in the long-term

Finally, we must address the question of long-term scalability. One risk of "mixing and matching" different brands of automation gear is that one manufacturer might discontinue a product or change its communication protocol, leaving you with a system that is impossible to upgrade. By sticking to a unified Siemens architecture, you are tapping into a global standard with a clear roadmap for the future.

In essence, you’re picking a system that will grow with you, rather than taking the rug out from under you right as you’re hitting your stride.

At the end of the day, you need to start somewhere, and your components are an excellent place to begin. A clear TIA portal experience, minimal downtime, data transparency, user experience, and scalability; all of these qualities come together to create the ideal system for control on your factory floor.

Whether you manufacture specialist parts or seek to triumph in the food and beverages industry, one thing is for sure: the right components go a long way toward helping you and your team do your best work.

CNC Design, your expert exclusive supplier for Siemens HMIs and controllers.

Our in-house automation designers are experienced with Siemens implementation across a variety of industries. Reach out today to discuss a new setup for your manufacturing floor that can grant you total control.